Tool Steel has excellent wear resistance and toughness, commonly used to make fixtures, tools, tool holders, gauges, and punches.

-

Capabilities

CNC Machining

Tight tolerances and finishing capabilities, as fast as 2 days.

Sheet Metal

Experience the versatility & cost efficiency with flexible application options.

Injection Molding

Production-grade steel tooling, as fast as weeks.

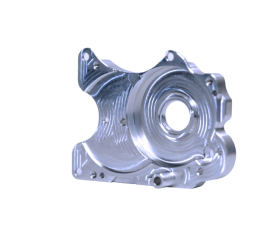

Die Casting

Create high quality custom mechanicals with precision and accuracy.

3D Printing

FDM, SLS, SLA, PolyJet, MJF technologies.

Compression Molding

Experience lower tooling costs with high-quality durable parts.

Urethane Casting

Production quality parts without the tooling investment.

![Out Platform]() Our Platform

Our Platform

Our digital supply chain platform provides high-quality, scalable manufacturing solutions and is built to handle the full product lifecycle.

Learn more -

Solutions

![Whats Next]() Manufacturing

Manufacturing

What's NextJoin thousands of customers who trust Fictiv with their production programs.

Learn more -

Industries

-

Resources

![]()

2025 State of Manufacturing & Supply Chain Report

Download report![]()

![]()

Airvine Scientific Success Story

The manufacturing behind Airvine's wireless Ethernet backbones.

Read case study![]()

-

Company

About Us

Learn about our company, leadership, and mission to transform manufacturing.

Learn more

Digital Platform

Accelerate development with instant quotes, expert DFM, and automated production updates.

Learn more

Global Network

Access a wide breadth of capabilities through our highly vetted network.

Learn more

Teams

Coordinate custom part sourcing across projects, teams, and even your entire company.

Learn more

Shows and Events

Join us for an upcoming trade show or webinar.

Learn more

Press

Read the latest news about Fictiv and access our Press Kit

Learn more

Careers We're hiring!

Explore opportunities to join the Fictiv team!

Learn more

Contact Us

Our team is on stand by, waiting to assist you.

Learn more